Trampolines

During the first quarter century of sailing and maintaining my boat I have been through several variations on multihull trampolines. The following is a summary of my experience.

Styles and Materials

Mesh By mesh I mean woven materials permeable to wind and water. The black polypropylene variant is common on beach cats. It is fairly light-weight and stands up well to sunshine – at least in Scandinavia. My trampolines just aft of the mast beam, on the sides of the engine pod, are made from this black mesh material. These trampolines have served me well since the mid 1990s. Seams need re-stitching on a regular basis but the material still looks sound to me. Polypropylene is a slippery material so seams need extra attention. The mesh itself is not slippery to be on whether dry or wet.

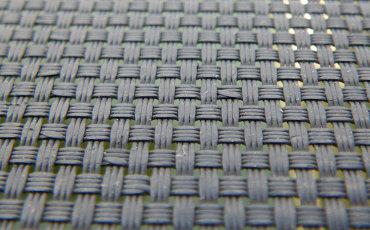

An alternative mesh material is constructed from PVC coated woven polyester. It comes in various weights and openness. There are some really tough qualities available. This material can be sewn or thermo-welded. I used this for aft trampolines before widening the boat in 1989. White looks nice but only for a short while.

Webbing A weave of webbing is a very strong if heavy trampoline material. Another drawback is the amount of sewing involved in making this type of trampoline – every crossing point need some stitching.

My first front trampoline was made from the type of webbing used for safety belts in cars. It was retired in favour of a net in 1989.

Nets I have experience of knotted Nylon and polyethylene nets on my boat. I have limited experience of knotless nets and I have visited a 52-foot cat fitted out with Dyneema nets. Advocates of knotless nets talk about the improved comfort of those nets. I have never felt knots to be a comfort issue and value the extra traction provided by the knots.

Nylon has turned out to be durable but it does absorb moisture and when it does it expands, and the trampolines go limp. This is not comfortable. One way to reduce this effect some is to wet the nets before bending them to the boat.

Polyethylene (PE) is lighter than Nylon and it does not absorb moisture so PE nets are the same dry or wet. Chafe resistance is not as good as for Nylon, however. One must minimise chafe and look after PE nets more than Nylon nets. All things' considered PE is what has worked best for me so far.

Practicalities

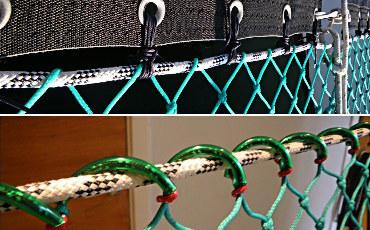

Chafe We do not want to go through our trampolines so they must be strong and durable. The upper photo of the two above shows where I see net chafe on my boat – where the net twine rubs over the 8 mm bolt rope. Good net tension reduces this movement and the chafe. This is the front trampoline, and the problem is small here. Chafe is more pronounced for the aft-most trampoline which sees much more traffic. The lower photo shows what I introduced for the most exposed edge for the 2012 season: 3 mm polyester line in a PVC hose.

Mesh/net orientation Should the fibres/twine be oriented parallel to hulls and beams or diagonally? The parallel scheme does result in a stiffer trampoline and for nets the chafe seem to be less of a problem. The diagonal variant is easier to set-up with even tension and single-twine load concentration is less likely. Looking around I see the parallel scheme dominates big time but for my nets I prefer the diagonal. The extra springiness is not a problem on this size of boat.

On the Firebird catamaran they used an interesting hybrid for the mesh trampoline aft of the main beam. This area is almost square and the trampoline came in two triangular pieces. There was no adjustment facilities around the trampoline area edges. All trampoline tensioning was done along the diagonal common to the two triangles.

2013 up-date

At the end of the 2012 I decided two decades of service was enough for the mesh-based pieces of the aft trampolines and ordered a brand new set of trampolines for the area between the main beam and the aft beam.